Introducing the Zero Press Series

Next-Generation Servo-Hydraulic Thermal Cycling Press

The Zero Press Series is an advanced Servo-Hydraulic Thermal Cycling Press designed to meet diverse needs, from material testing and production to high-pressure molding.

- Zero Press Lab – Designed for new material development and testing, this model provides precise pressure and temperature control for cutting-edge research applications.

- Zero Press Production – Optimized for high-efficiency manufacturing, this streamlined model includes only the essential functions needed for seamless production line integration.

- Zero Press High-Pressure – Engineered for molding and bonding at 40 kgf/cm² to 100 kgf/cm², this model is ideal for plastic deformation of resins and wood materials.

With the Zero Press Series, powered by Servo-Hydraulic Thermal Cycling Technology, you can enhance production efficiency and achieve superior product quality.

Explore each model in detail to find the best solution for your needs.

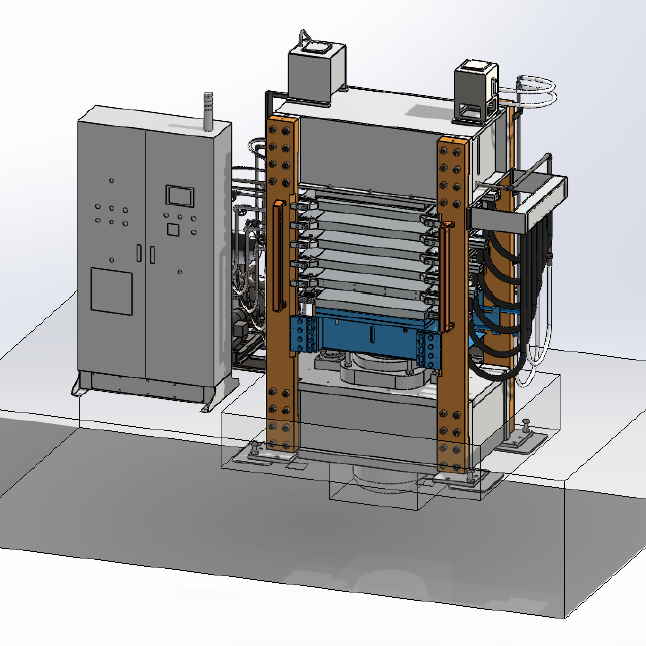

– Zero Press Lab –

Accelerate Research & Development with a Servo-Hydraulic Thermal Cycling Press

The Zero Press Lab is a Servo-Hydraulic Thermal Cycling Press designed specifically for new material development and a wide range of testing applications.

We precisely assess our customers’ needs and apply our expertise to configure the optimal options. This press offers flexible customization to seamlessly integrate into your testing environment, expanding the possibilities for research and development.

If you’re unsure about the ideal specifications for your testing equipment or need a press machine tailored to specific test conditions, we provide in-depth consultations to develop the best solution for your lab.

Let’s create not just a press machine for experiments, but a press machine that drives innovation in your research.

Key Features

✅ Precision Pressure Control

- Fully automated servo-controlled hydraulic pump operation within a 0 to 100-ton range.

- Accurately replicates gradual pressure increase and decrease, making it ideal for repeated condition testing.

✅ High-Accuracy Thickness Management

- Maintains workpiece thickness within the specified range through precise platen position control after pressing.

✅ Advanced Temperature Control

- Heated platens ensure uniform heating at 200°C ±3°C.

- Independent upper and lower platen temperature settings, adjustable up to 340°C.

✅ Integrated Cooling Function

- Enables cooling while applying pressure, with an option for single-sided cooling.

Options & Customization

The Zero Press Lab, a Servo-Hydraulic Thermal Cycling Press, can be customized with optimal options tailored to your specific testing requirements.

Leveraging our extensive experience in testing press machine installations, we provide custom solutions to accelerate your research and development.

If you need to conduct tests under specific conditions or require more precise temperature and pressure control, feel free to consult with us.

– Zero Press Production –

Servo-Hydraulic Thermal Cycling Press Optimized for Production Lines

The Zero Press Production is a Servo-Hydraulic Thermal Cycling Press specifically designed for production lines, engineered to meet the unique demands of manufacturing environments.

After establishing the optimal manufacturing process during prototyping and testing phases, we integrate only the essential functions necessary to build a high-efficiency production press.

Unlike the testing phase, production lines require a broader perspective, considering factors such as pre- and post-processing, factory layout, safety, and operator usability. We carefully incorporate feedback from all relevant departments, making precise adjustments to ensure seamless operation and prevent potential issues.

Let’s create a high-performance press machine that is truly efficient and user-friendly, striking the perfect balance between productivity and safety in your manufacturing environment.

Core Design Concepts

✅ Maximizing Productivity with Only Essential Functions

- The Zero Press base model is customized by integrating only the essential functions required for your production line, eliminating unnecessary complexity.

- Optimization options, such as multi-stage press integration, are available to further enhance productivity.

✅ Designed for Seamless Production Line Integration

- Ensures smooth operation by considering pre- and post-process connections.

- Incorporates a factory layout- and operator-friendly design, reducing workload and improving overall efficiency.

✅ Ensuring Safety Compliance

- Meets company-specific safety standards, proactively mitigating risks.

- For example, we confirm calendar timer usage feasibility in advance to comply with operational policies.

- Instead of area sensors, we implement physical safety fences and other high-effectiveness measures to ensure platen safety.

Customization & Pre-Implementation Review

In larger production facilities, various departments often have differing requirements and requests.

To prevent future issues, we conduct thorough pre-implementation coordination with all stakeholders during the design phase.

By integrating all production requirements from the early design stages, we create a Servo-Hydraulic Thermal Cycling Press that offers maximum usability and efficiency in real-world operations.

The Zero Press Production is more than just a press machine—it is a comprehensive solution for optimizing your entire production line.

With meticulous attention to detail, we deliver a high-performance hot press machine that truly meets the demands of modern manufacturing.

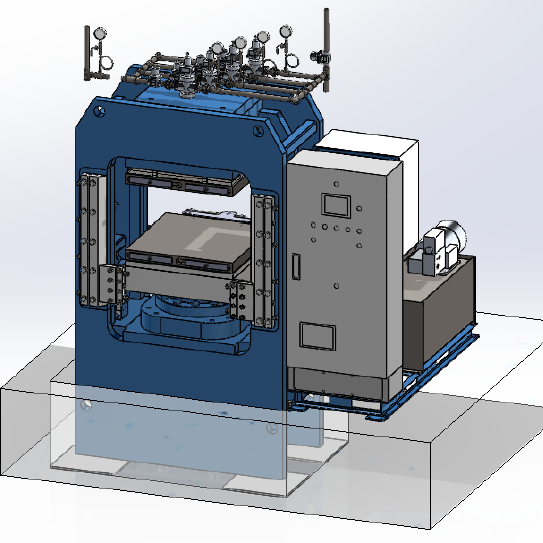

– Zero Press High-Pressure –

Servo-Hydraulic Thermal Cycling Press Specialized for High-Pressure Molding

The Zero Press High-Pressure is a Servo-Hydraulic Thermal Cycling Press capable of applying high pressure from 40 kgf/cm² to 100 kgf/cm² to various workpieces.

Designed for plastic deformation, densification, and bonding of resins and wood materials, this model is optimized for processes requiring exceptionally high pressing forces.

Leveraging the core advantages of the Zero Press Series, this press offers:

- Variable pressure control over time, enabling gradual or staged pressure adjustments.

- Energy-efficient operation, maintaining high pressure for extended periods.

- Seamless transition to cooling while maintaining pressure, stabilizing internal structural changes before releasing the load.

To ensure optimal process integration, we provide thorough consultations, including spacer and mold selection, to determine the most suitable specifications for your application.

Core Design Concepts

✅ High-Pressure Control

- Capable of applying 40 kgf/cm² to 100 kgf/cm² of pressure.

- Supports time-controlled pressure adjustments, enabling gradual pressure changes and prolonged pressure holding for optimal processing.

✅ Optimized for Plastic Deformation & Bonding

- Specifically designed for plastic deformation, bonding, and compression molding of resins and wood materials.

- Enables a seamless transition from pressing to cooling, ensuring stable internal material changes before pressure release.

✅ Energy-Efficient Design

- Supports long-duration pressing (over 2 hours) with minimal power consumption.

- Ensures efficient production with optimized energy use.

✅ Integration with Molds & Spacers

- Designed for precise deformation control with mold and spacer compatibility.

- Final specifications are determined through testing and consultation, ensuring the best fit for your application.

Customization & Pre-Implementation Review

For high-pressure pressing, selecting the optimal control methods and auxiliary equipment is critical, depending on pressing conditions and material properties.

For example, you may require:

- Gradual pressure adjustments for densification processes.

- Long-duration pressing with minimal energy consumption.

- A stable cooling transition while maintaining pressure to preserve material integrity.

We conduct a comprehensive analysis during the design stage to develop a highly optimized Servo-Hydraulic Thermal Cycling Press tailored to your specific requirements.

The Zero Press High-Pressure is engineered to enable precise bonding and molding under extreme conditions.

Let’s work together to develop a customized solution that perfectly fits your production needs.